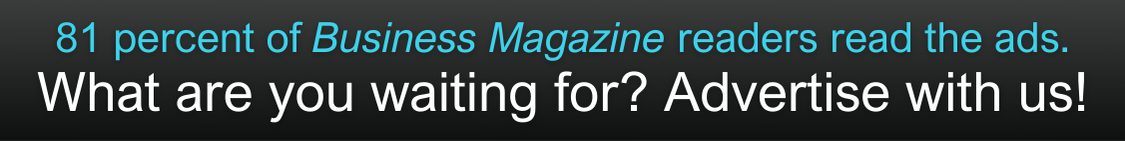

They started out small. The company began fabricating steel, the old bridge in Oil City is a testament to their work.

But they found that building at their plant in Albion and shipping to the site was better, but they needed trailers to do that, and the rest is Made in America history. Rogers is, and has always been a family run business and has been at the forefront of innovation in the trailer industry.

Jay Kulyk, President Rogers Brothers Corp., said: “We developed many of the things in trailers that are commonplace today, the gooseneck, the detachable gooseneck, all things that originated in the building.”

These days Rogers builds trailers that are customer designed to the customer’s needs, from start to finish.

Nicholas Kulyk, plant manager, said: “We cut the steel, flame burning as well as plasma, hi-speed band saws.”

Then it’s off to the set up area where the material is welded together and the trailer is underway. And the workers doing the job say what they put together far exceeds what comes from overseas.

Eddie Figuerona, welder, said: “Most of our products are hand-made, takes a lot of hand fabrication.”

Some of the monster haulers take a few weeks to finish, but when they’re ready to roll, the customer knows quality in this Made in America is front and center.

These trailers have to be durable, they’re built to last and structural failure is not an option.

I think from Made in America here, for our plant and our product, I think its important to our customer because they work in the U.S. We are supporting our community, that’s our work.

It’s very important we have our business here. It provides jobs for local people, we provide taxes and stuff for the school district and government.