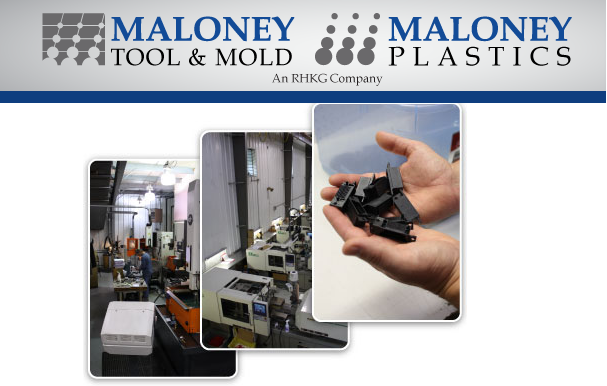

MEADVILLE – Maloney Tool & Plastics (an RHKG Holdings Inc. Company) recently added new equipment to its plastics injection molding and its tooling operations.

The addition includes two injection molding machines – one, a 110 ton Arburg E-Drive horizontal injection press, while the other is an 85-ton Toshiba that is equipped with an 18 mm barrel giving it a .53 ounce shot size. Both presses are equipped with Yushin sprue pickers and Keyence cameras for mold protection. The company also added two new E-Darts from RJG Inc. A new ERP system from IQMS is also in the implementation phase with a “go-live” date of January 1, 2016.

The Plastics shop is an ISO 9001:2008 certified facility serving the auto, aerospace, appliance, medical and consumer electronics industries. The facility also supplies full 100-percent inspection, PPAP and first article inspection for part validation.

Additionally, the Tool shop recently installed a Mitsubishi Electric model EA12V EDM sinker to increase capacity, lower costs and improve quality for sinker EDM work. The new sinker was installed in a remodeled section of the EDM room, which will soon be completed. The equipment operators returned recently from an extensive training session in Chicago to learn how to operate the new machine. The tool shop has also started a new apprentice program to begin training the next generation of toolmakers. Currently the company has one apprentice in the program with plans to add a second apprentice in the second quarter of 2016.

According to officials of the Meadville-based company, these recent additions will improve capacity, lower energy costs, increase capabilities and improve quality for customers. “With continuing upgrades and an emphasis on training and education of our associates our company strives to be one of the industry leaders in the manufacturing field,” stated CEO Paul Huber.

For more information, visit www.maloneycos.com.