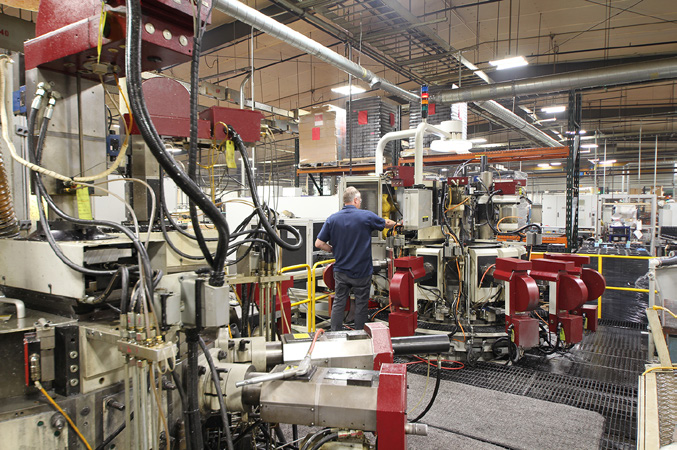

When you think of contract precision machining the term “job shop” may come to mind. A job shop is typically a small, lower volume contract manufacturer that specializes in routing parts through several labor-intensive operations to complete an order. In 1984, Gerald B. Eighmy took what he knew about “job shop” work and began American Turned Products here in Northwest PA. “We do the tough stuff” was not only a phrase coined by the original founder, but it was a mantra of what American Turned Products stood for: a solution for customers. Now 40 years later, ATP is so much more.

Three Generations

Gerald’s sons, Scott and Harry Eighmy, took their father’s mission and have further transformed American Turned Products from a small job shop into a premier high-volume, high-precision contract manufacturer of components for the Defense, Automotive, Fluid Power, Oil & Gas, and other markets both domestically and worldwide. Scott’s son, Jerry Eighmy, also joined the ATP Team to carry on the Eighmy-entrepreneur legacy for years to come.

Technically Advanced

With two facilities, and more than 90,000 square feet of manufacturing space, ATP’s skilled engineering and production teams, technically advanced machining and inspection processes, and commitment to continuous improvement ensure delivery of parts that compete with anyone in the world: on time and defect free.

In addition to adding CNC equipment, designed to reduce the number of secondary operations typically required for precision parts, ATP is continually looking for ways to improve the efficiency of its overall operations. Inspired by Paul Akers’s 2 Second Lean™, ATP has really focused the past few years on growing people and building a fun, simple, lean culture. Efforts to further this culture include daily communication meetings, which are about sharing ideas and improvements; the ATP Business School, which is a 10-week classroom course offered to all employees that covers all areas of the business; and encouraging before and after videos of any improvements made at work or at home.

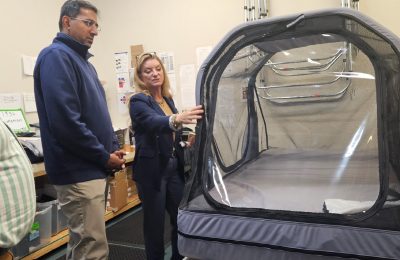

Another way ATP is advancing growth and improvements is engaging in the upgrade of its “systems”. Over the next years, ATP’s strategic initiatives are based in Industry 4.0 visions — “where our shop floors are fully connected, with real-time analytics, automation, and additional advanced-manufacturing technologies,” says Jerry Eighmy, manager.

“Everywhere you look the world is now driven by data and data analytics. We need to continue to enhance our tools for data collection and analysis to stay ahead of the competition. By understanding how our processes are performing, not only can we be informed owners/managers but our employees become owners of their own processes and make good decisions on productivity and quality,” states Harry Eighmy, co-owner and chief operating officer at American Turned Products.

Looking to the Future

Scott Eighmy, co-owner and chief executive officer, also added, “as we position ourselves for the future, we need to make small incremental improvements every day. If we all do that, we will ensure American Turned Products remains a member of the vital core manufacturing base in Northwest PA for years to come. The Eighmy family is extremely proud of our 40-year history in Northwest Pennsylvania. The constant over the years has been treating customers, suppliers, and employees fairly and with integrity in everything we do. ‘People Providing Excellence’ has been our motto and has never been truer today.”

Headquarters:

7626 Klier Drive

Fairview, PA 16415

Phone: 814/474-4200

Website: atpteam.com